Proficient in the design and processing of various non-standard sheet metal and chassis, we can design and customize various sheet metal accessories according to customer requirements. Drawing design, drawing and disassembly, typesetting, blanking, welding, riveting, etc. provide a one-stop solution for sheet metal processing.

Mold is an industrial product that shapes materials in a specific structural form in a certain way. At the same time, it is also a production tool that can produce industrial product parts with certain shape and size requirements in batches. Whether it is airplanes, cars, teacups, or nails, almost all industrial products must rely on molds. The high precision, high consistency and high productivity of parts produced by molds are unmatched by any other processing method. Molds determine to a large extent the quality, efficiency and new product development capabilities of products. Therefore, molds have the honorary title of "Mother of Industry". We are committed to providing customers with the design and manufacturing of high-precision molds. Solve mold design problems, product appearance and later product industrialization issues for customers. Strive to achieve a series of industrial designs such as product serialization and personalization. Ensure the sustainable development of the integration of corporate culture and product image. Products involved in industries: medical equipment, auto parts, communication electronics, household appliances, etc.

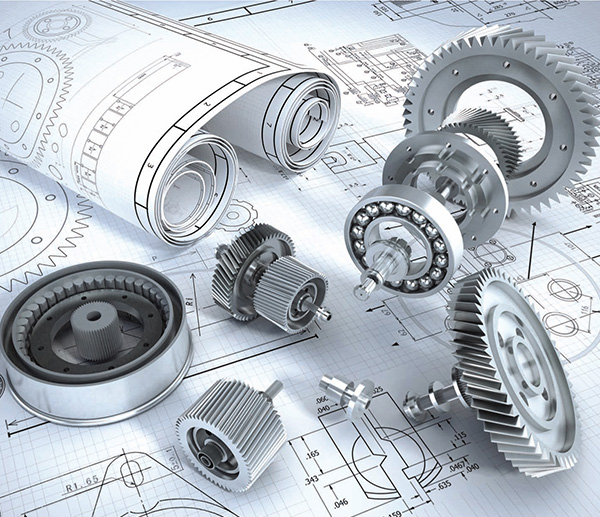

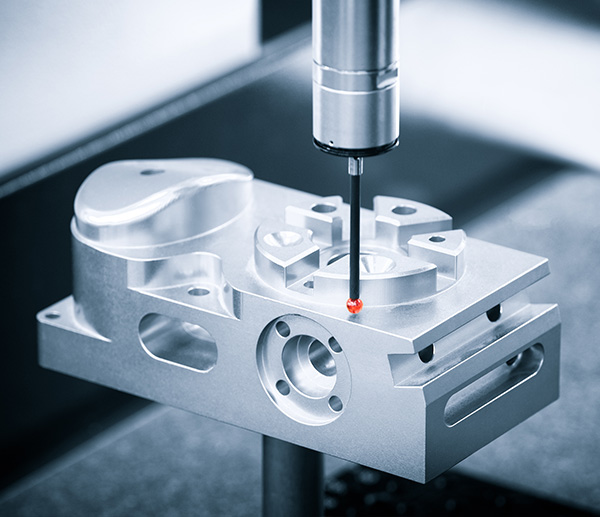

Non-standard parts refer to those mechanical parts that differ from national or industry standards in terms of size, shape, material and accuracy. Such parts often need to be specially designed and manufactured according to the requirements of specific machinery and production lines. It may have general functionality but have special requirements in certain critical dimensions, shapes, materials, or accuracy. Therefore it is not universal and interchangeable. The cost of non-standard parts is usually higher than that of standard parts because their products require corresponding quality control from casting to finishing, and the process is complex and highly variable.